Top 10 Major Inventions of the Industrial Revolution

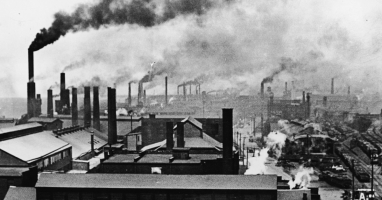

The Industrial Revolution, which took place between roughly 1760 and some time between 1820 and 1840, was the adoption of new manufacturing techniques in Great ... read more...Britain, continental Europe, and the United States. This transition involved switching from manual to machine-assisted production techniques, new ways of producing chemicals and iron, increased steam and water power use, created machine tools and emerged the mechanized industrial system. Here are the 10 major inventions of the Industrial Revolution.

-

James Hargreaves invented the spinning jenny. Around 1720, he was born in Oswaldtwistle, near Blackburn. Blackburn, a town of roughly 5,000 people, was famous for the creation of "Blackburn greys", linen warp, and cotton weft cloths imported from India. Typically, they were sent to London to be printed.

Cotton output couldn't keep up with the textile industry's demand at the time, so Hargreaves spent some time thinking about how to enhance the process. The flying shuttle (John Kay 1733) had doubled the productivity of the weavers, and now the spinning jenny could meet that need by raising the productivity of the spinners even more. The thread produced by the machine was coarse.

Hargreaves came up with the idea for a metal frame with eight hardwood spindles at one end. On that frame, a set of eight rovings was mounted to a beam. When fully stretched, the rovings flowed through two horizontal wood bars that could be clasped together. The spinner's left hand might be used to draw these bars along the top of the frame, extending the thread. The spinner spun the thread with his right hand by rapidly turning a wheel, which caused all of the spindles to revolve. The thread was wound onto the spindle when the bars were returned. The threads were guided to the proper location on the spindle using a pushing wire.

Hargreaves kept the machine a secret for a while, but he did make a few for his own burgeoning business. The drop in yarn prices enraged Blackburn's big spinning community. After breaking into his house and smashing his machinery, he was forced to flee to Nottingham in 1768. The hosiery industry, as well as knitted silks, cotton, and wool, were all centered here. With the help of a joiner named Thomas James, he started up a shop making jennies in secret for a Mr. Shipley. On Mill Street, he and James started a textile business. He received a patent (no. 962) for his invention, the Spinning Jenny, which was a machine for spinning, drawing, and twisting cotton, on July 12, 1770.

As one of the major inventions of the Industrial Revolution, the spinning jenny was successful because it could hold more than one ball of yarn, allowing it to produce more yarn in less time and at a lower cost. If the flying shuttle had not been designed and deployed in textile plants, the spinning jenny would not have been as successful. Its success was restricted by the requirement to prepare the rovings on a wheel, which was hampered by the necessity to the card by hand. It was widely used in the cotton and fustian industries until around 1810. The spinning mule took the place of the spinning jenny. The Slubbing Billy is based on the jenny, which was adapted for the slubbing process.

en.wikipedia.org

interestingengineering.com -

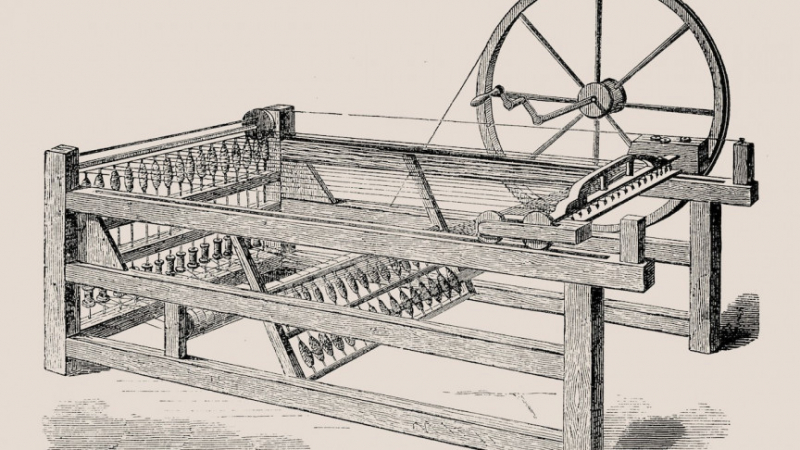

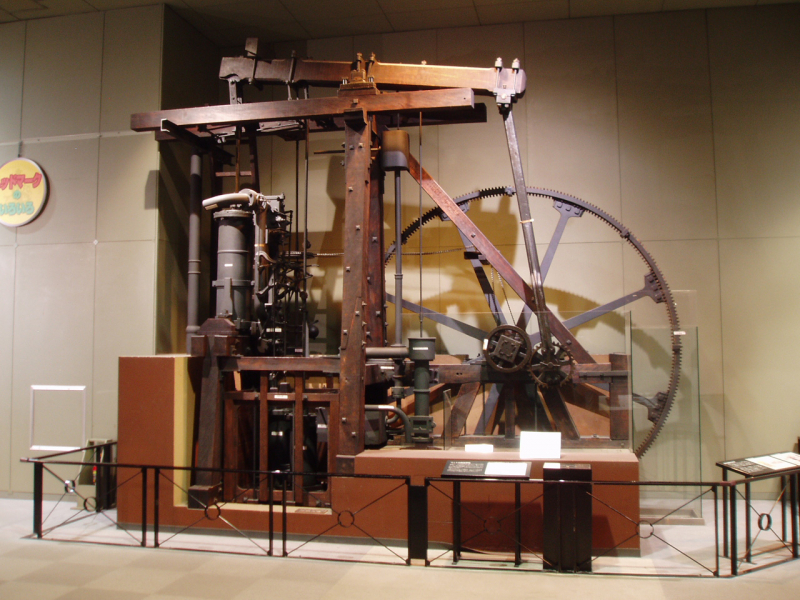

One of the major inventions of the Industrial Revolution is the Newcomen engine. Thomas Newcomen invented the atmospheric engine in 1712, and it is commonly referred to as a Newcomen engine. The engine worked by condensing steam brought into the cylinder, creating a partial vacuum that allowed the piston to be pushed into the cylinder by air pressure. It was the first practical machine to use steam to perform mechanical tasks. Newcomen engines were widely employed in Britain and Europe, primarily to pump water from mines. Hundreds were built over the course of the 18th century.

Later engine designs by James Watt were an upgraded version of the Newcomen engine that nearly doubled fuel efficiency. Many atmospheric engines were changed to the Watt type at a fraction of the cost of replacing the fuel. As a result, Watt is now more famous than Newcomen when it comes to the invention of the steam engine.

Because the pump apparatus was heavier than the steam piston, the beam at rest was pump-side down/engine-side up, a position known as "out of the house." To start the engine, the regulator valve V was opened, allowing steam from the boiler to enter the cylinder and fill the space beneath the piston. After that, the regulator valve was closed, and the water injection valve V' was temporarily opened and closed, spraying cold water into the cylinder. The steam was condensed, and a partial vacuum was generated beneath the piston. The pressure differential between the atmosphere above the piston and the partial vacuum below it then forced the piston down, causing the power stroke and lifting the pump gear. The cylinder was then refilled with steam, which destroyed the vacuum and forced the condensate down the sinking or "eduction" pipe. The weight of the pump and gear returned the beam to its original position as the low-pressure steam from the boiler flowed into the cylinder, while also driving the water up from the mine. This cycle was repeated at a rate of around 12 times per minute.

The Newcomen engine was widely used in mining by 1725, particularly in collieries. It remained in place for the rest of the century with little alteration. The Newcomen engine was used to pump municipal water supplies in some places; for example, the first Newcomen engine in France was erected in 1726 at Passy to pump water from the Seine to the city of Paris. It was also used to indirectly power machines by returning water from below a water wheel to a reservoir above it, allowing the same water to move the wheel once more. Coalbrookdale was one of the first places where this happened. To return water to the pool above the Old Blast Furnace, a horse-powered pump was erected in 1735. In 1742- 1743, it was replaced by a Newcomen engine. Horsehay and Ketley furnaces, as well as Madeley Wood or Bedlam furnaces, were built in Shropshire in the 1750s and were powered in a similar method. The latter appears to have had only a tank into which the water was pumped, rather than a pool above the furnace. Engine pumping was less prevalent in other industries, but Richard Arkwright utilized one to give additional power to his cotton mill.

historycrunch.com

rootsofprogress.org -

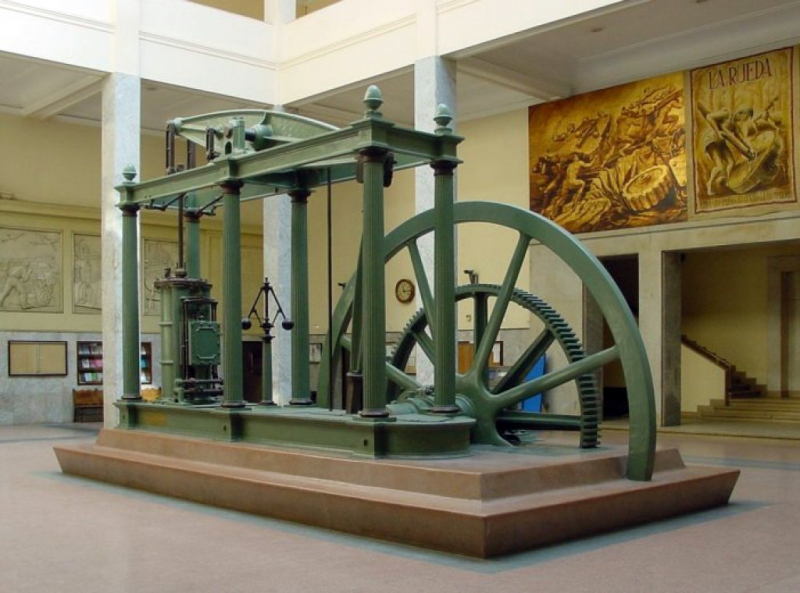

The Watt steam engine, also known as the Boulton and Watt steam engine, was an early steam engine that was one of the Industrial Revolution's driving forces. From 1763 through 1775, James Watt worked on the design intermittently with Matthew Boulton's help. Watt's concept saved so much more fuel than previous designs that it was licensed solely on the basis of the quantity of fuel it would save. Watt never stopped working on the steam engine, inventing double-acting designs (with two cylinders) and a variety of rotary power systems. Watt's design became identified with steam engines, and it took many years before important alternative designs began to take their place.

Watt worked on the concept for several years, adding the condenser and making improvements to almost every aspect of the system. Watt, for example, conducted a long series of tests on techniques to seal the piston in the cylinder, which significantly reduced leakage during the power stroke and prevented power loss. All of these changes resulted in a more dependable design that used half the amount of coal to provide the same amount of power.

The first commercial version of the new design was sold to the Carron Company ironworks in 1776. Watt continued to refine the engine, and in 1781, he introduced a mechanism that used sun and planet gear to convert the engines' linear speed to circular motion. This made it helpful not just in the original pumping job, but also as a direct replacement for roles that previously required the use of a water wheel. This was a pivotal point in the industrial revolution since power sources could now be situated anywhere instead of requiring a sufficient water source and topography, as they had in the past. Boulton began designing a variety of equipment that utilized this rotary power, as well as the first modern industrialized factory, the Soho Foundry, which manufactured new steam engine designs. Watt's early engines were similar to the original Newcomen designs in that they used low-pressure steam and relied entirely on air pressure to generate power. When rival companies introduced high-pressure steam engines in the early 1800s, Watt was hesitant to follow suit due to safety concerns.

Watt began researching the use of higher-pressure steam, as well as designs with many cylinders in both the double-acting and multiple-expansion concepts, in order to improve the performance of his engines. The parallel motion was invented for these double-acting engines, allowing the piston rods of individual cylinders to move in straight lines, keeping the piston true in the cylinder, while the walking beam end moved in an arc, similar to a crosshead in later steam engines.

The Old Bess of 1777, located in the Science Museum in London, is the oldest surviving Watt engine. The Smethwick Engine, which was first used in May 1779 and is now housed at Thinktank in Birmingham, is the world's oldest working engine. The 1812 Boulton & Watt engine at the Crofton Pumping Station in Wiltshire is the oldest still in its original engine house and capable of fulfilling the purpose for which it was intended. This was used to pump water for the Kennet and Avon Canal; the contemporary pumps are turned off on various weekends throughout the year, and the two steam engines at Crofton continue to fulfill this role.

en.wikipedia.org

madeupinbritain.uk -

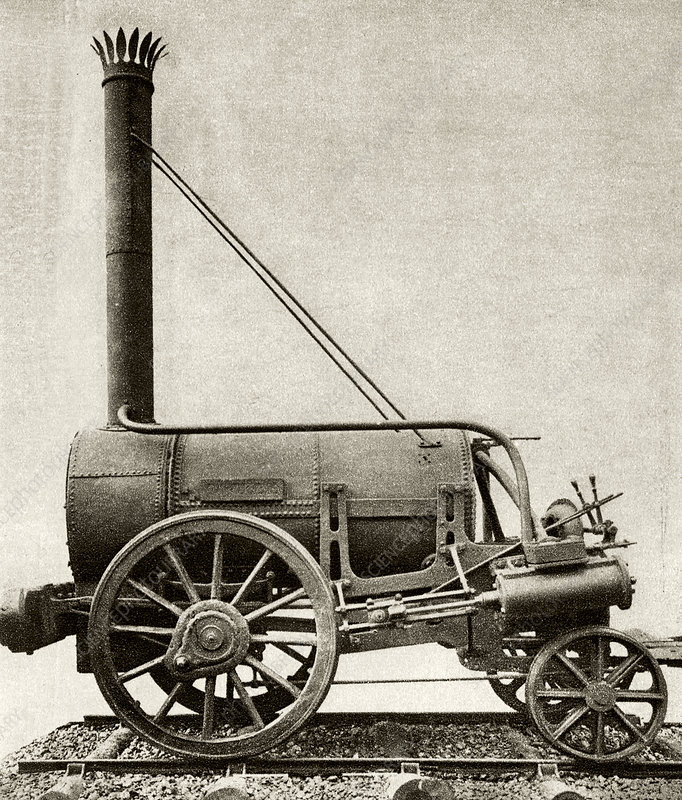

Stephenson's Rocket is a 0-2-2 wheel layout early steam locomotive. It was built for the Liverpool and Manchester Railway's (L&MR) Rainhill Trials, which were held in October 1829 to demonstrate that improved locomotives would be more efficient than stationary steam engines. Robert Stephenson designed the Rocket in 1829 and built it at his company's Forth Street Works in Newcastle upon Tyne. The Rocket was not the first steam locomotive, but it was the first to combine many advances to create the most sophisticated locomotive of the day. It is the most well-known example of Stephenson's progressive locomotive design, which served as the model for most steam engines for the next 150 years.

The locomotive featured a large smokestack chimney up front, a cylinder boiler in the middle, and a separate firebox at the back. Two external cylinders arranged at an angle drove the huge front pair of wooden wheels. The 0-2-2 wheel configuration was achieved by not coupling the smaller rear wheels to the driving wheels. The locomotive was created by Stephenson specifically for the Rainhill Trials and the competition's requirements. Because the first railway was designed more for passengers than freight, the rules prioritized speed and required reliability, but the locomotive's weight was also strictly limited. The weight restriction for six-wheeled locomotives was six tons, while for four-wheeled locomotives it was four and a half tons. The weight of the train to be hauled, in particular, had to be no more than three times the locomotive's actual weight. Whatever the size of previously successful locomotives, Stephenson knew that this new competition would favor a rapid, light locomotive with relatively limited hauling capability.

Between 1830 and 1840, the history is rather vaguely documented. Rocket worked on the Liverpool and Manchester Railway from 1830 until 1834. Stephenson's Rocket was employed on Lord Carlisle's Railway in Brampton, Cumberland (now Cumbria), England, between 1836 and 1840 after serving on the L&MR. The engine was built as a prototype to win a speed trial, but it was quickly replaced by better designs, such as Stephenson's Northumbrian and Planet designs, both of which were released in 1830. Within a few years, the Rocket had been significantly altered to resemble the Northumbrian class. When compared to the angled configuration when new, the cylinders were moved to a near-horizontal position, the firebox capacity was increased, the design was simplified, and the locomotive was given a drum smokebox.

The locomotive was sold for £300 in 1836 and put into service on the Brampton Railway in Cumberland, which had recently switched to Stephenson gauge. After service, it remained at Tindale until 1862, when it was donated to the London Museum. The Thompsons of Milton Hall, near Brampton, donated Rocket to the Patent Office Museum in London (now the Science Museum) in 1862. The locomotive is still in existence, albeit it hasn't been used since it was turned into a museum exhibit. It was on display at the Science Museum for 150 years, though in a considerably different state than it was during the Rainhill Trials. From September 25, 2018, until September 8, 2019, it was on display at the Science and Industry Museum in Manchester, first in Newcastle and later in Manchester. It has been on display at York's National Railway Museum since 2019.

collection.sciencemuseumgroup.org.uk

sciencephoto.com -

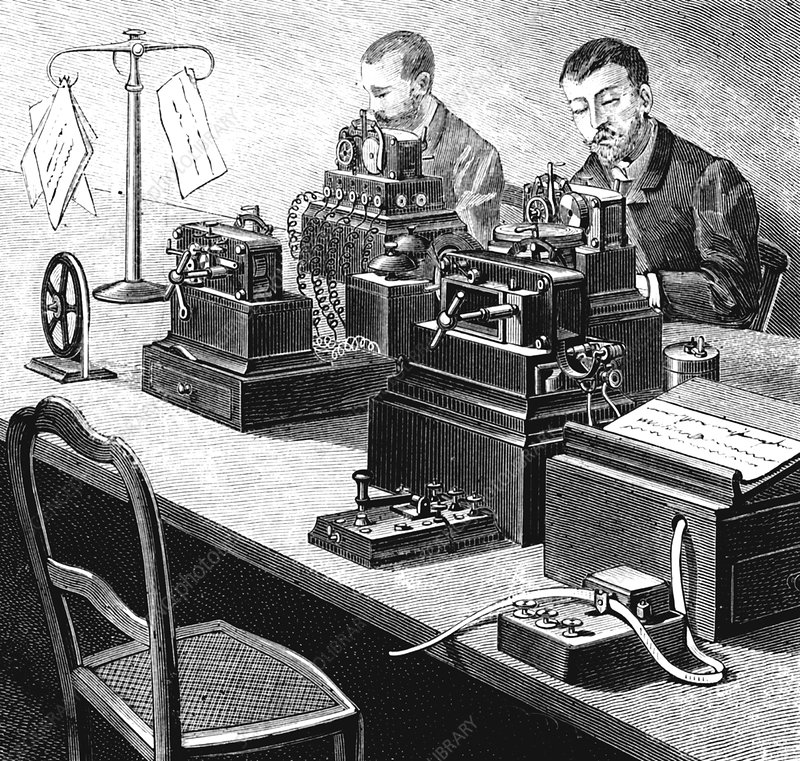

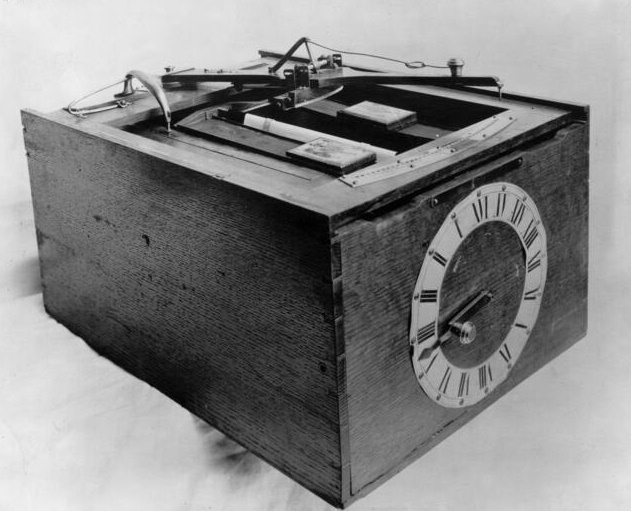

The Cooke and Wheatstone telegraph, one of the major inventions of the Industrial Revolution, designed in the 1830s by English inventor William Fothergill Cooke and English scientist Charles Wheatstone, was an early electrical telegraph system. It was a type of needle telegraph and the first commercially available telegraph system. The receiver was made up of a number of needles that could be moved around on a board by electromagnetic coils. Early customers who didn't want to learn codes and employers that didn't want to spend on employee training loved this feature.

Later systems did away with the letter board and read the code straight from the movement of the needles. Because the number of needles was reduced, the codes became more complicated. The decision was driven by the desire to cut costs by reducing the number of telegraph cables utilized, which was proportional to the number of needles. As the insulation on some of the early installations decayed, some of the original cables became unsuitable, the change became increasingly necessary. Cooke and Wheatstone's most successful method was a one-needle system that lasted into the 1930s.

The killer John Tawell has apprehended thanks to Cooke and Wheatstone's telegraph. When it was discovered that Tawell had boarded a train to London, the telegraph was used to send a signal to the Paddington terminus, where he was caught. The uniqueness of this use of the telegraph in crime-fighting drew a lot of attention and led to a greater public acceptance and use of the telegraph.

On the new railways being built in London, the use of the electric telegraph began to rise. When the London and Blackwall Railway opened in 1840, it was fitted with the Cooke and Wheatstone telegraph, and many others followed. The Blackwall Railway's distance (four miles) was too far for steam signaling, and the engineer, Robert Stephenson, was a staunch supporter of the electric solution. Along with the London and South Western Railway, an 88-mile line from Nine Elms to Gosport was completed in February 1845, significantly longer than any other railway at the time. The Admiralty paid half the capital cost and £1,500 per annum for a private two-needle telegraph on this line to connect it to its base in Portsmouth, finally replacing the optical telegraph. The Electric Telegraph Company was founded in September 1845 by investors John Lewis Ricardo and Cooke. The Cooke and Wheatstone patents were purchased by this company, which solidified the telegraph industry. The enterprise was nationalized in 1869 and absorbed into the General Post Office. On British railways, the one-needle telegraph was a huge success, and 15,000 sets were still in service by the end of the nineteenth century. Some were still in use in the 1930s.

The Cooke and Wheatstone telegraph served primarily the United Kingdom and the British Empire. It was, nevertheless, used in Spain for a time. After the telegraph sector in the United Kingdom was nationalized, the Post Office gradually replaced the various systems it had inherited, such as the Cooke and Wheatstone telegraph, with the Morse telegraph system.

en.wikipedia.org

sciencephoto.com -

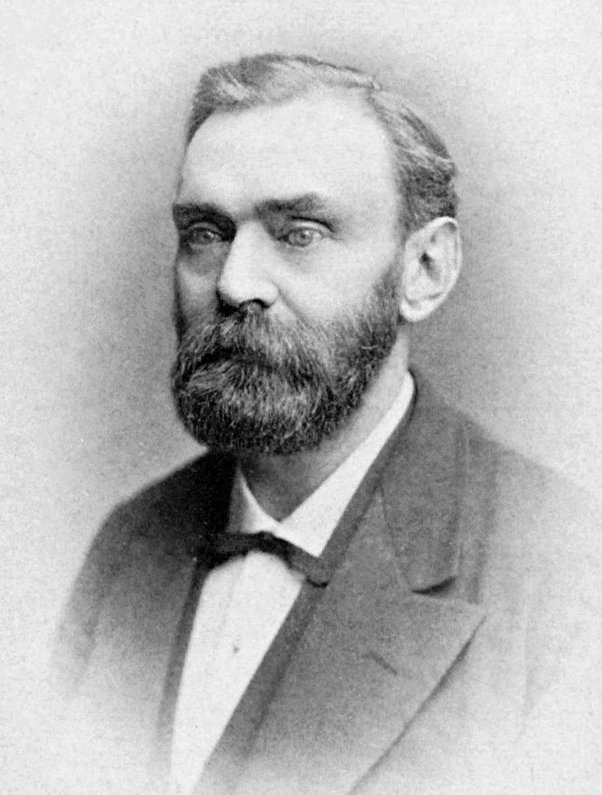

Nitroglycerin, sorbents (such as powdered shells or clay), and stabilizers are the main ingredients in the explosion known as dynamite. It was created in Geesthacht, Northern Germany, by Swedish engineer and scientist Alfred Nobel, who obtained a patent for it in 1867. As a more potent substitute for black powder, it quickly acquired widespread use.

Today, the mining, quarrying, construction, and demolition industries are the main ones that employ dynamite. For trenching applications, dynamite is still the product of choice, and it is occasionally employed as a cost-effective explosive booster for ANFO charges.

The first manageable explosive that was more powerful than black powder was dynamite, which was created by Swedish chemist Alfred Nobel in the 1860s. When he was 17 years old, Alfred was forced to live abroad for two years. While there, he met the Swedish engineer John Ericsson and studied under renowned scientist Théophile-Jules Pelouze and his student Ascanio Sobrero, who had created nitroglycerin for the first time in 1847. Nobel first came upon nitroglycerin in France, which Pelouze warned against utilizing as a commercial explosive due to its high sensitivity to shock.

Nobel was interested in nitroglycerin's potential as an explosive and filed the first of several hundred patents in 1857, most of which were related to air pressure, gas, and fluid gauges. Nobel experimented with numerous mixes of nitroglycerin and black powder with the help of his father and brother Emil. Nobel created the detonator, also known as the blasting cap, which allowed a controlled explosion to be set off from a distance using a fuse as a solution for how to properly detonate nitroglycerin. Using a blasting cap composed of a copper percussion cap and mercury fulminate, Nobel carried out his first successful detonation of pure nitroglycerin in the summer of 1863. Alfred Nobel applied for patents for the blasting cap and his process for making nitroglycerin by combining sulfuric acid, nitric acid, and glycerin in 1864. Emil and several other people were killed in an explosion at the factory on Immanuel Nobel's farm in Heleneborg on September 3, 1864, while conducting nitroglycerin experiments. After that, Alfred established Nitroglycerin Aktiebolaget AB in Vinterviken to carry on his work at a more remote location. The next year, he relocated to Germany and established Dynamit Nobel.

Despite the development of the blasting cap, nitroglycerin's volatility prevented it from being used as a commercial explosive. In order to address this issue, Nobel tried to blend it with a different material that would make it safe for handling and transportation while maintaining its explosive properties. He attempted using cement, coal, and sawdust in combination but failed. The nitroglycerin was successfully stabilized into a portable explosive by using diatomaceous earth, fossilized algae that he collected from the Elbe River near his plant in Hamburg.

On 7 May 1867 in England and on 19 October 1867 in Sweden, Nobel received patents for his innovations. As a safe replacement for nitroglycerin and black powder, dynamite quickly attained widespread use after being invented. The patents were carefully controlled by Nobel, and companies that copied them without a license were immediately shut down. However, a few American businessmen circumvented the patent by employing absorbents other than diatomaceous earth, such as resin.

wikiwand.com

quora.com -

A photograph is an image made by light striking a photosensitive surface, either photographic film or an electronic image sensor like a CCD or CMOS chip. It is also referred to as a photo, image, or picture. Nowadays, the majority of photos are taken with a smartphone/camera, which employs a lens to concentrate the scene's visible light wavelengths into a replica of what the human eye would perceive. Photography is the art and science of producing such images.

Nicéphore Niépce's "heliography" process, which relies on bitumen, was used to create the first-ever permanent photograph, a contact-exposed replica of etching, in 1822. A few years later, in 1826, at Le Gras, France, the first images of a real-world scene were captured using a camera obscura, although Niépce's method was not sensitive enough to be useful in that application; a camera exposure lasting for hours or days was necessary. Niépce and Louis Daguerre formed a collaboration in 1829, and the two men worked together to develop a similar but superior procedure.

Daguerre focused on silver halide-based substitutes after Niépce's passing in 1833. He developed a layer of light-sensitive silver iodide on a silver-plated copper sheet by exposing it to iodine vapor, then exposed it to the camera for a short period of time, developed the resulting latent image to visibility with mercury fumes, and finally submerged the plate in a hot salt solution to remove the remaining silver iodide, making the results light-fast. He gave his own name, Daguerre, to the first practical method for creating images taken with a camera. On January 7, 1839, the world was informed of its existence, but it wasn't until August 19 that the workings were made known. Portrait photography became genuinely feasible and very well-liked when other innovators produced advancements that decreased the necessary exposure time from a few minutes to a few seconds.

otosection.com

en.wikipedia.org -

A mechanical or electromechanical keyboarding device is referred to as a typewriter. A typewriter typically contains a variety of keys, and by pressing each key deliberately against the paper with a type element, a different single character is formed on the paper. A typewriter user was also referred to as a "typewriter" at the end of the nineteenth century.

Even though the first commercial typewriters were released in 1874, offices did not start using them often until the middle of the 1880s. With the exception of personal handwritten correspondence, the typewriter swiftly became a necessary instrument for almost all writing. It was frequently used by freelance writers, in workplaces, for business correspondence in residences, and by students composing essays.

Up until the 1980s, typewriters were a common sight in most offices. After that, personal computers with word processing software started to substantially replace them. However, typewriters are still widely used in various regions of the world. Due to a lack of continuous, stable energy in many Indian cities and towns, typewriters are still used, particularly on the roadway and in legal offices. Although the roots of the QWERTY keyboard layout, which was designed for typewriters in the 1870s and remains the standard for computer keyboards, whether it was developed for mechanical reasons or to suit the operator, particularly Morse code operators, are still debated.

E. Remington and Sons, IBM, Godrej, Oliver Typewriter Company, Olivetti, Royal Typewriter Company, Smith Corona, Underwood Typewriter Company, Adler Typewriter Company, and Olympia-Werke were a few notable typewriter makers.

alamy.com

msn.com -

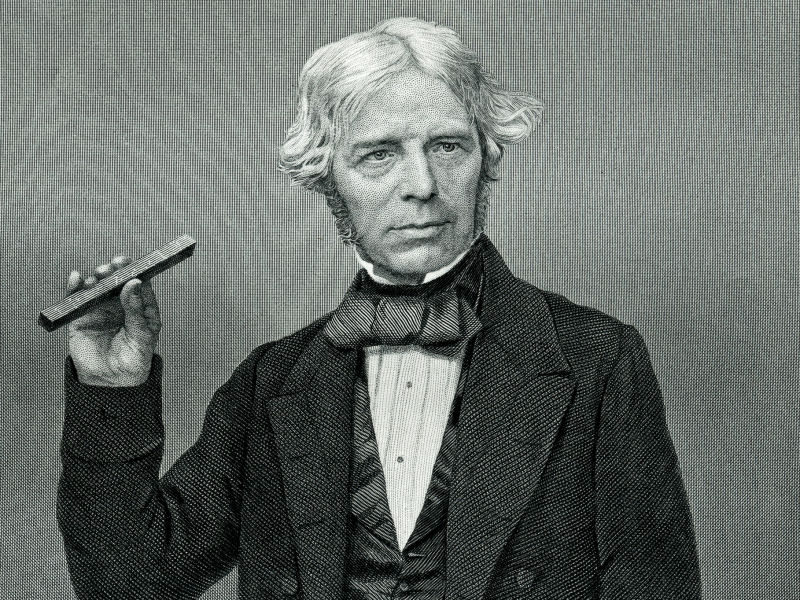

The electric generator is a device used in the production of electricity that transforms motive power (mechanical energy) into electrical energy for use in an external circuit. Steam turbines, gas turbines, water turbines, internal combustion engines, wind turbines, and even hand cranks are examples of mechanical energy generators. British physicist Michael Faraday created the Faraday disk, the first electromagnetic generator, in 1831. Electric power grids are powered almost entirely by generators.

Electric motors, which share many characteristics with generators, are used to convert electrical energy back into mechanical energy. It is possible to mechanically drive a variety of motors to produce power; usually, these motors make good manual generators.

Michael Faraday discovered the electromagnetic generator's working theory between 1831 and 1832. An electromotive force is produced in an electrical conductor that surrounds a fluctuating magnetic flux, according to the theory, which was later known as Faraday's law. A copper disc rotating between the poles of a horseshoe magnet was used to create the first homopolar generator, often known as the Faraday disk. It generated a tiny DC voltage.

Due to self-canceling counterflows of current in areas of the disk not affected by the magnetic field, this design was wasteful. Directly beneath the magnet, the current was generated, but in areas outside the magnetic field's effect, the current would flow backward. The pickup wires' power output was constrained by this counterflow, which also caused the copper disc to heat up unnecessarily. This issue would be resolved in later homopolar generators by employing a collection of magnets positioned around the disc's edge to maintain a constant field effect in one current-flow direction.

Due to the output voltage's solitary current channel through the magnetic flux, another drawback was that it was extremely low. Researchers discovered that adding additional rounds of wire to a coil might generate higher, more beneficial voltages. Generators could simply be created to produce any desired voltage by adjusting the number of spins because the output voltage is proportional to the number of turns. All following generator designs had wire windings as a standard component.

skullsinthestars.com

thoughtco.com -

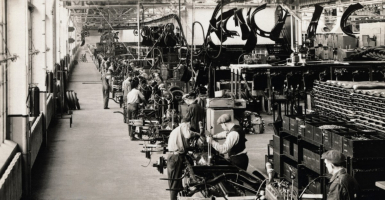

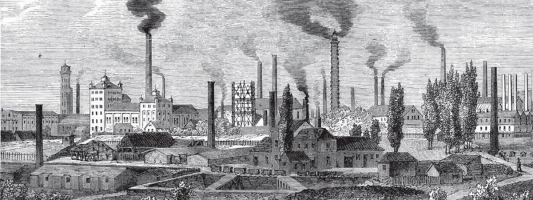

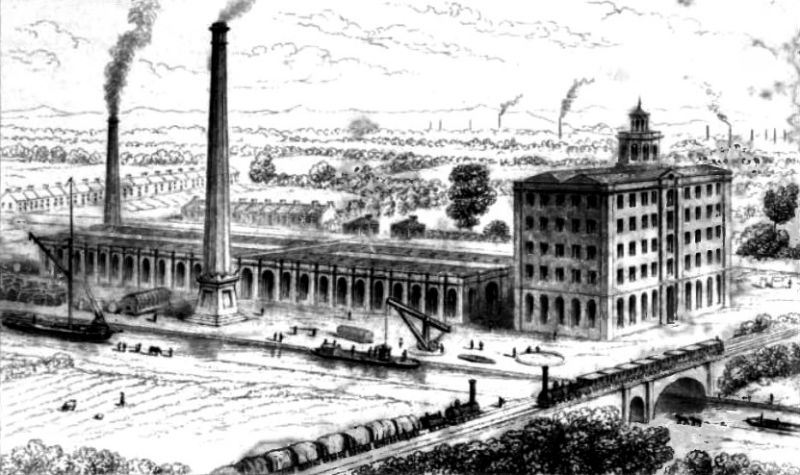

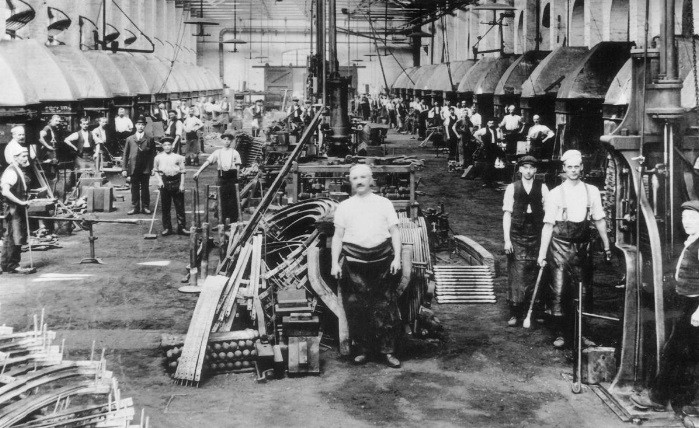

With the introduction of machines, modern factories began popping up first in Britain and subsequently across the world. The water-powered Derby silk mill built by John Lombe, which was in use by 1721, was one of the first factories. At Warmley, close to Bristol, a fully integrated brass mill was operating by 1746. At one end, raw materials were inserted, smelted into brass, and then transformed into pans, pins, wire, and other products. On-site housing was available for the workers. Other well-known early manufacturers who used the factory system included Josiah Wedgwood in Staffordshire and Matthew Boulton at his Soho Manufactory.

The prototype of the contemporary factory is given to Richard Arkwright. After receiving his water frame's patent in 1769, he built Cromford Mill in Derbyshire, England, greatly enlarging the nearby village of Cromford to accommodate the new immigrant employees. The invention of machinery that was too huge to fit in a worker's hut necessitated the development of a new method for managing the workers. Workdays lasted from dawn to sunset, six days a week, just like they had for the farmer. Overall, this strategy effectively turned both skilled and unskilled workers into commodities that could be replaced. The first successful cotton-spinning facility in the world, Arkwright's factory unmistakably mapped out the future of the sector and inspired numerous imitators.

Due to the larger-scale factories' enormous technological and managerial advantages over the smaller artisan shops, mechanized factories replaced traditional artisan shops as the major kind of industrial institution between 1770 and 1850. The cotton and wool textile industries were the first to build factories (using the factory system). Mechanized shoe manufacturing and the creation of machinery, particularly machine tools, were features of later generations of factories. Following this were companies that produced cast-steel plows, reapers, and locomotives as well as rolling mills, foundries, and locomotive works that served the railroad industry. Beginning in the 1880s, bicycles were mass-produced.

One of the first factories to utilize contemporary materials handling, such as cranes and rail tracks within the buildings for carrying large things, was the Nasmyth, Gaskell, and Company's Bridgewater Foundry, which opened for business in 1836.

After the AC motor was developed, which could run at a constant speed depending on the number of poles and the current electrical frequency, large-scale electrification of enterprises started around 1900. Line shafts were first equipped with larger motors, but as soon as modest horsepower motors were readily accessible, industries shifted to unit drive. Line shaft removal released layout restrictions, enabling more effective factory layouts. Using relay logic, sequential automation was made possible by electrification.

foundations.uwgb.org

libguides.stalbanssc.vic.edu.au