The modern factories

With the introduction of machines, modern factories began popping up first in Britain and subsequently across the world. The water-powered Derby silk mill built by John Lombe, which was in use by 1721, was one of the first factories. At Warmley, close to Bristol, a fully integrated brass mill was operating by 1746. At one end, raw materials were inserted, smelted into brass, and then transformed into pans, pins, wire, and other products. On-site housing was available for the workers. Other well-known early manufacturers who used the factory system included Josiah Wedgwood in Staffordshire and Matthew Boulton at his Soho Manufactory.

The prototype of the contemporary factory is given to Richard Arkwright. After receiving his water frame's patent in 1769, he built Cromford Mill in Derbyshire, England, greatly enlarging the nearby village of Cromford to accommodate the new immigrant employees. The invention of machinery that was too huge to fit in a worker's hut necessitated the development of a new method for managing the workers. Workdays lasted from dawn to sunset, six days a week, just like they had for the farmer. Overall, this strategy effectively turned both skilled and unskilled workers into commodities that could be replaced. The first successful cotton-spinning facility in the world, Arkwright's factory unmistakably mapped out the future of the sector and inspired numerous imitators.

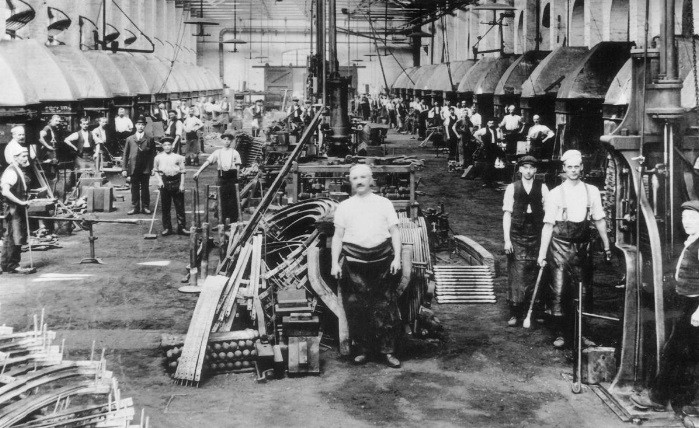

Due to the larger-scale factories' enormous technological and managerial advantages over the smaller artisan shops, mechanized factories replaced traditional artisan shops as the major kind of industrial institution between 1770 and 1850. The cotton and wool textile industries were the first to build factories (using the factory system). Mechanized shoe manufacturing and the creation of machinery, particularly machine tools, were features of later generations of factories. Following this were companies that produced cast-steel plows, reapers, and locomotives as well as rolling mills, foundries, and locomotive works that served the railroad industry. Beginning in the 1880s, bicycles were mass-produced.

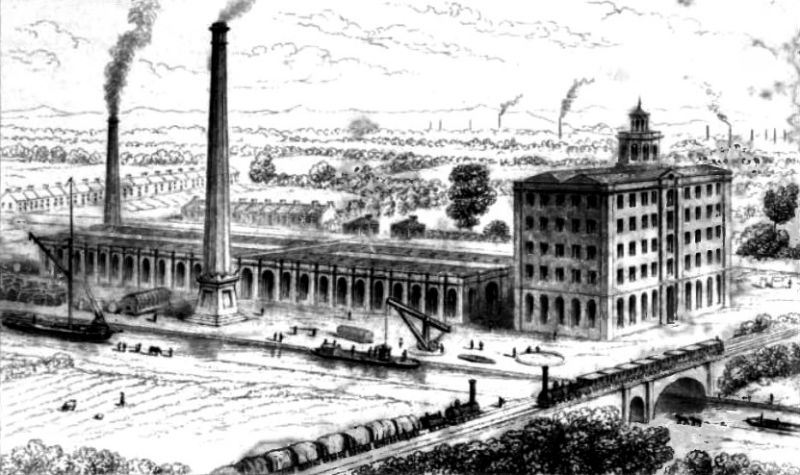

One of the first factories to utilize contemporary materials handling, such as cranes and rail tracks within the buildings for carrying large things, was the Nasmyth, Gaskell, and Company's Bridgewater Foundry, which opened for business in 1836.

After the AC motor was developed, which could run at a constant speed depending on the number of poles and the current electrical frequency, large-scale electrification of enterprises started around 1900. Line shafts were first equipped with larger motors, but as soon as modest horsepower motors were readily accessible, industries shifted to unit drive. Line shaft removal released layout restrictions, enabling more effective factory layouts. Using relay logic, sequential automation was made possible by electrification.