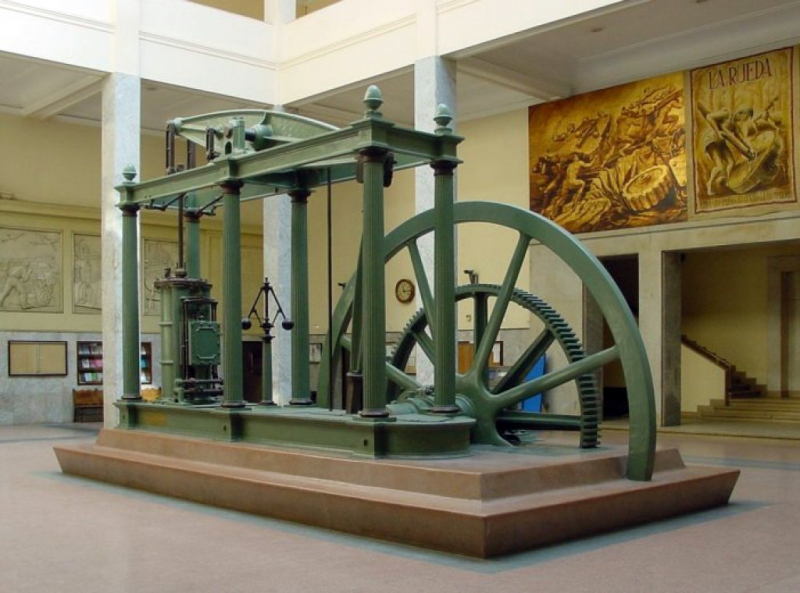

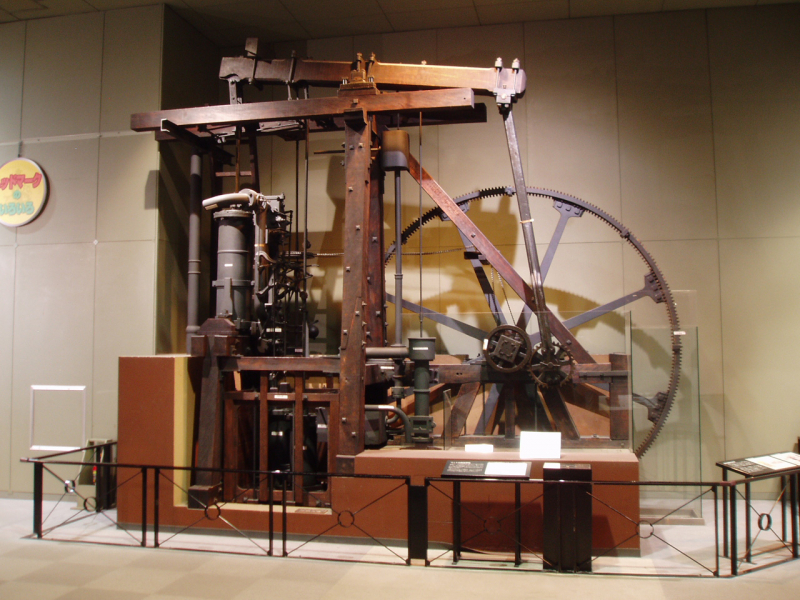

The Watt steam engine

The Watt steam engine, also known as the Boulton and Watt steam engine, was an early steam engine that was one of the Industrial Revolution's driving forces. From 1763 through 1775, James Watt worked on the design intermittently with Matthew Boulton's help. Watt's concept saved so much more fuel than previous designs that it was licensed solely on the basis of the quantity of fuel it would save. Watt never stopped working on the steam engine, inventing double-acting designs (with two cylinders) and a variety of rotary power systems. Watt's design became identified with steam engines, and it took many years before important alternative designs began to take their place.

Watt worked on the concept for several years, adding the condenser and making improvements to almost every aspect of the system. Watt, for example, conducted a long series of tests on techniques to seal the piston in the cylinder, which significantly reduced leakage during the power stroke and prevented power loss. All of these changes resulted in a more dependable design that used half the amount of coal to provide the same amount of power.

The first commercial version of the new design was sold to the Carron Company ironworks in 1776. Watt continued to refine the engine, and in 1781, he introduced a mechanism that used sun and planet gear to convert the engines' linear speed to circular motion. This made it helpful not just in the original pumping job, but also as a direct replacement for roles that previously required the use of a water wheel. This was a pivotal point in the industrial revolution since power sources could now be situated anywhere instead of requiring a sufficient water source and topography, as they had in the past. Boulton began designing a variety of equipment that utilized this rotary power, as well as the first modern industrialized factory, the Soho Foundry, which manufactured new steam engine designs. Watt's early engines were similar to the original Newcomen designs in that they used low-pressure steam and relied entirely on air pressure to generate power. When rival companies introduced high-pressure steam engines in the early 1800s, Watt was hesitant to follow suit due to safety concerns.

Watt began researching the use of higher-pressure steam, as well as designs with many cylinders in both the double-acting and multiple-expansion concepts, in order to improve the performance of his engines. The parallel motion was invented for these double-acting engines, allowing the piston rods of individual cylinders to move in straight lines, keeping the piston true in the cylinder, while the walking beam end moved in an arc, similar to a crosshead in later steam engines.

The Old Bess of 1777, located in the Science Museum in London, is the oldest surviving Watt engine. The Smethwick Engine, which was first used in May 1779 and is now housed at Thinktank in Birmingham, is the world's oldest working engine. The 1812 Boulton & Watt engine at the Crofton Pumping Station in Wiltshire is the oldest still in its original engine house and capable of fulfilling the purpose for which it was intended. This was used to pump water for the Kennet and Avon Canal; the contemporary pumps are turned off on various weekends throughout the year, and the two steam engines at Crofton continue to fulfill this role.